FY09 MCON P-181 WHARF UPGRADE AND WAREHOUSE, U.S. NAVY SUPPORT FACILITY – DIEGO GARCIA, B.I.O.T.

This Design-Build project located in Diego Garcia (DG) included the upgrade to the potable water system, waste water treatment system, bilge and oily waste water treatment systems and the construction of storage facilities to support the land class ship operations at DG.

In order to appreciate the challenges encountered throughout the project, we must first recognize the geographic remoteness of DG. Diego Garcia is a narrow atoll, one of the 52 islands in the Chagos Archipelago, which extends over an area of 25,900 square kilometers. The coral atoll is horseshoe-shaped with an opening approximately 6.4km wide where the lagoon transitions into the Indian Ocean. The land distance from tip-to-tip of the atoll is roughly 60km, while the total land area is about 2,720 hectares.

In order to appreciate the challenges encountered throughout the project, we must first recognize the geographic remoteness of DG. Diego Garcia is a narrow atoll, one of the 52 islands in the Chagos Archipelago, which extends over an area of 25,900 square kilometers. The coral atoll is horseshoe-shaped with an opening approximately 6.4km wide where the lagoon transitions into the Indian Ocean. The land distance from tip-to-tip of the atoll is roughly 60km, while the total land area is about 2,720 hectares.

The FY09 Project P-181 provides facilities to support the relocation of land class vessel due to closure of the ship homeport. This was the second phase to support the ship at its new location in a timely manner and to improve overall operations of the U.S. Navy Support Facility (NSF) in DG.

The magnitude of logistics involved with getting to and from Diego Garcia was the single most significant challenge associated with the project. Limited flights in and out of DG added to the difficulty in coordinating the delivery of manpower, specialists and supplies to the island.

To ensure timely completion, BCC submitted a cost loaded project schedule updated each month for the duration of the project. A 3 week look-ahead schedule was also provided and discussed during the weekly coordination meetings.

Careful and extensive planning proved to be an essential element to the overall success of the project. Black Construction Corporation (BCC) imported all resources (e.g. cement, aggregates, etc…) from off-island due to the blatant lack of resources on the island to support this type of construction. BCC also brought in all equipment and man camp supplies from our Guam home office via a chartered tug and barge. Major materials came from the Mainland US via Singapore, then on to Diego Garcia via MSC regular service to the island. It took approximately 2 months for each incoming shipment of materials to arrive in DG. Advanced coordination and planning was also crucial to the scheduling for various off-island Tech Reps to initiate the training and start-up of the systems.

BCC maintained superior quality throughout the duration of the contract by implementing the 3 Phases of Control for each definable feature of work:

1) Preparatory Phase (prior to the start of each definable feature of work): Review all documentation and contract requirements. Confirm all materials are on-hand and that all preliminary work is complete. Review safety issues.

2) Initial Phase: Performed at the beginning of each definable feature. Check preliminary work. Establish level of workmanship. Check dimensional requirements. Discuss/confirm safety compliance.

3) Follow-Up Phase: Daily inspections/checks to confirm compliance.

There were no recordable safety violations and no lost time was incurred during the performance of this contract!

There were no recordable safety violations and no lost time was incurred during the performance of this contract!

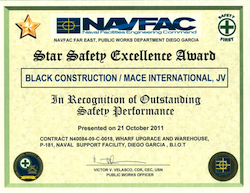

BCC was selected as the recipient of the PWD Safety Through Awards and Recognition (STAR) program award for its outstanding safety performance during the execution of this contract. The award is a significant achievement and awarded only to those companies which have demonstrated a corporate safety posture throughout the life of their contract.

Notable Features of Work:

- Controlled Humidity Warehouse is a single-storey 1090 sm Pre-Engineered Building

- 2000 sm open storage pad

- Two sludge drying beds and three sludge pumps and a filtrate pump

- 180 sm Water Treatment Plant Building

- Potable 70,000 gals water storage tank and 9000 linear feet of water line

- Oily wastewater and recovery storage tanks

[hr]